Blogs

Computer-aided design (CAD) plays a critical role in the manufacturing industry, and CNC machining is one of the most popular manufacturing processes that relies on CAD.

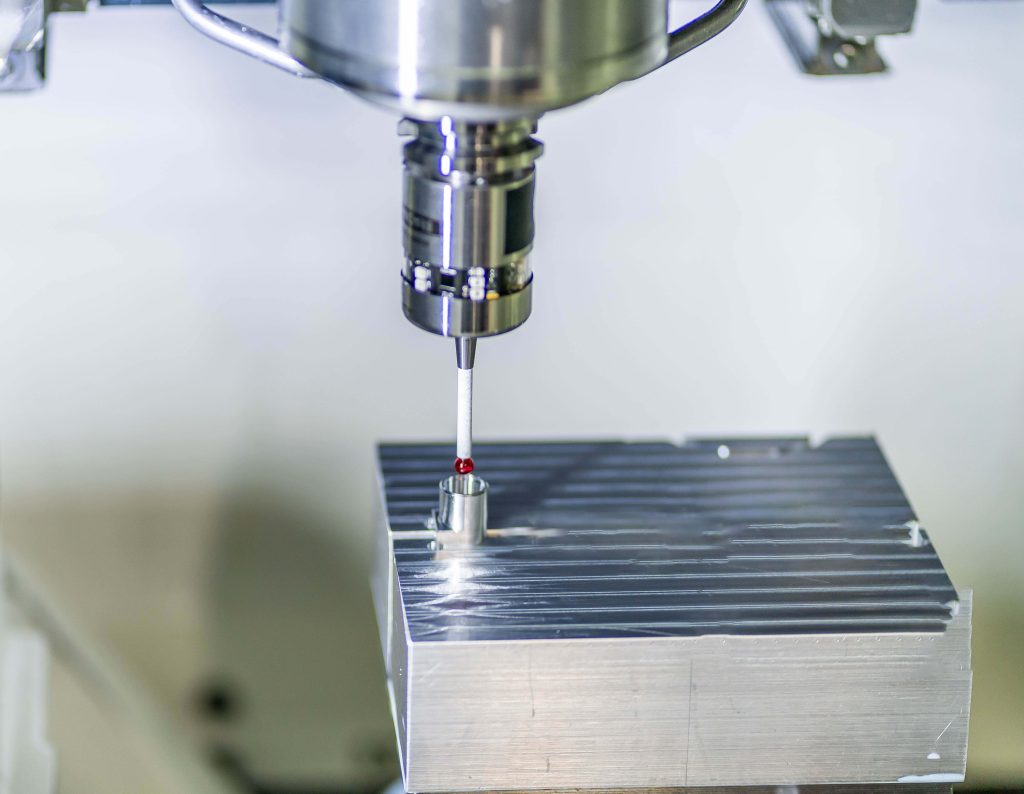

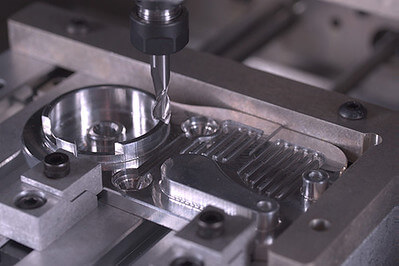

Complex machining refers to the production of parts and components with intricate shapes and high tolerances, and it often requires the use of a combination of different machining techniques and tools.

CNC-machining is a process that involves technology to fabricate precise parts and components from various materials, such as Aluminum, Metals and Plastics. It is a highly

G-code, which stands for "geometric code," is the programming language used by CNC machines. It uses to generate instructions for CNC machines to utilize when making physical parts.

Material damage during CNC machining can have expensive repercussions that affect the operations. Small errors or flaws in the finished product could require costly rework or Scrap.

Manufacturing complex parts using CNC machining comes with a unique set of challenges that can be overwhelming for machinists.

Precision, efficiency, and innovation are just a few elements of the manufacturing industry, and CNC machining has been a game-changer in achieving those goals.

Is your machine shop having difficulty meeting the standards of sustainability? Are you seeking solutions to cut waste and save energy while enhancing productivity? If this is the case, you are not alone. Many machine shops are

With the rise of AI-powered and machine-learning, CNC machine software and interfaces, you don't want to be left behind while thinking you still have 500